Prysmian BICON CFRZHMPJ Chemical & Fire Resistance Cable Jointing Kits

Description

Prysmian BICON CFRZHMPJ Chemical & Fire Resistance Cable Jointing Kits are Immersion & Zero Halogen Straight Joints for NEK 606 BFOU Fire Resistant Power & Control Cables: Single & Multi Core 1.5mm² to 300mm².

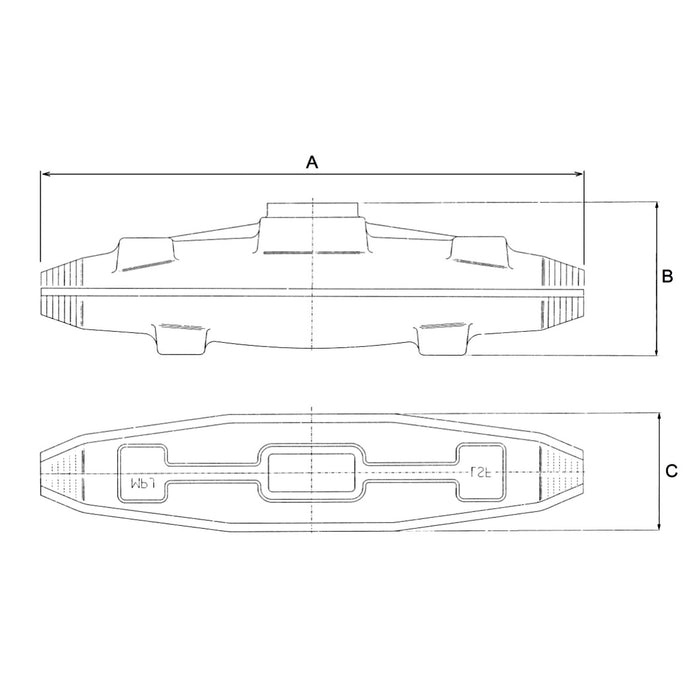

Shell Dimensions

| Product No. | A (mm) | B (mm) | C (mm) |

|---|---|---|---|

| CFRZHMPJ3 | 405 | 100 | 80 |

| CFRZHMPJ4 | 430 | 110 | 90 |

| CFRZHMPJ5 | 560 | 160 | 130 |

| CFRZHMPJ6 | 740 | 180 | 145 |

| CFRZHMPJ7 | 870 | 190 | 145 |

Features & Benefits

- Rated voltage 1000V

-

Tested and approved to:

=> BS EN 50393:2015 – Test methods and requirements for accessories for use on distribution cables of rated voltage 0,6/1,0 (1,2) kV - IEC 60331-1 (90mins Fire & Vibration + 15 Mins Immersion)

- BS 6387:2013 – Test method for resistance to fire of cables required to maintain circuit integrity under fire conditions (categories C, W & Z).

- IEC 61034-2:2005+A1:2013 – Measurement of smoke density of cables burning under defined conditions.

- BS 6899—oil resistance

- Low Hazard Isocyanate free JEM resin.

- Twin pack mixing in clear laminate sachets.

- Extremely low viscosity resin with enhanced adhesion.

- Rigid glass reinforced phenolic joint shells which are Chemical resisting, Fire retardant and LSOH.

- Slim-line design for use with compression connectors.

- Requires compression connectors which come separately.

Technical Information

In this range a Phenolic resin shell is used to provide excellent resistance to Hydrocarbons found in Oil, Gas and Petrochemical installations. Tests to demonstrate the chemical resistance of both the shell and the sealing putty have been carried out to BS6899 using ASTM oils, numbers 2 and 3. This calls for 24 hour immersion at 100°C and specifies permissible changes in mechanical properties before and after ageing. In each case minimal changes were observed after immersion in both oils, under conditions where most conventional polymers used in cable construction would not survive.

- Low Voltage Straight Joints for 600/1000 Volt NEK 606 BFOU fire Performance cables.

- Tested and approved to BS EN 50393 : 2015

-

Fire tests on complete joints to:

=> IEC 60331-1 (90mins + 15 mins immersion)

=> BS 6387 categories C, W & Z